-

The first delivers of our product to the Republic of India, in August 2017.

-

Launch of joint industrial tests commissioned by the Indian concern NTPC. Large European manufacturer of De-NOx systems from the Austrian offices of YARA holding, the Dutch manufacturer of high-quality enamel coating Ferro Techniek BV and the Russian manufacturer of special profiles for efficient heat-exchange The Alternative Ltd. participate in test routine.

-

The agreements on product promotion in the Asian region.

-

Joint participation The Alternative Ltd. and FerroTechniek BV at POWER GEN India & Central Asia 2017, in May 2017.

-

In December 2016, one in two power stations in Russia worked with CMKA® heat-exchange elements. -

Enter to the Central American market, production delivery in the Republic of Guatemala.

-

Negotiations were held over beginning of joint activities with Ferro Techneik BV.

-

СМКА ® heat-exchange elements were the leader at Russian market. Enter to the European and Asian markets.

Joint participation The Alternative Ltd. and Paragon at POWER GEN in Los Angeles.

-

The offer on joint activity was received from the American manufacturer of the thermal equipment - Paragon.

-

The company annually confirms compliance with international quality standards.

The first delivers of our product to the Republic of Moldova.

-

The company continues to be the leader in sales of heat-exchange elements in the Russian Federation. Employees actively prepare a base for entering the European and Asian markets.

-

The company's quality management system is the first among the companies of the shipbuilding cluster was certified in accordance with the requirements of the new military standard GOST RV 0015.002.2012.

-

The third manufacture was started. Manufacturing of metal structures of industrial and building purpose.

-

New contracts on shipbuilding were signed.

-

The cost of production of CMKA® heat-exchange elements has been significantly reduced due to the introduction of new technologies.

-

The high quality and competitiveness of the Russian innovative product were confirmed by participation in European tenders.

In May 2012, the company organized an exclusive exhibition of paintings by the Montenegrin artist Vojislav Stanic in Arkhangelsk. This was his third exhibition in Russia, the first two were held in Moscow.

-

In December 2011, one in ten power stations in Russia worked with CMKA® heat-exchange elements.

-

Licenses for the construction and repair of B and BT was obtained.

-

The shipbuilding specialists successfully developed new territories in the east and west of the country - works were conducted in Komsomolsk-on-Amur and in Kaliningrad.

-

Official certified dealers emerged in 2011.

-

New Quality Management System (ISO 9001) was implemented.

-

Internal audit was carried out, goals and tasks were set in accordance with the requirements of the international quality system.

-

Modernization of production was carried out, new automated equipment was purchased and installed. This allowed to double the production capacity.

-

The shipbuilding industry was developing successfully, the company signed a subcontract to build frames for chemical tankers.

-

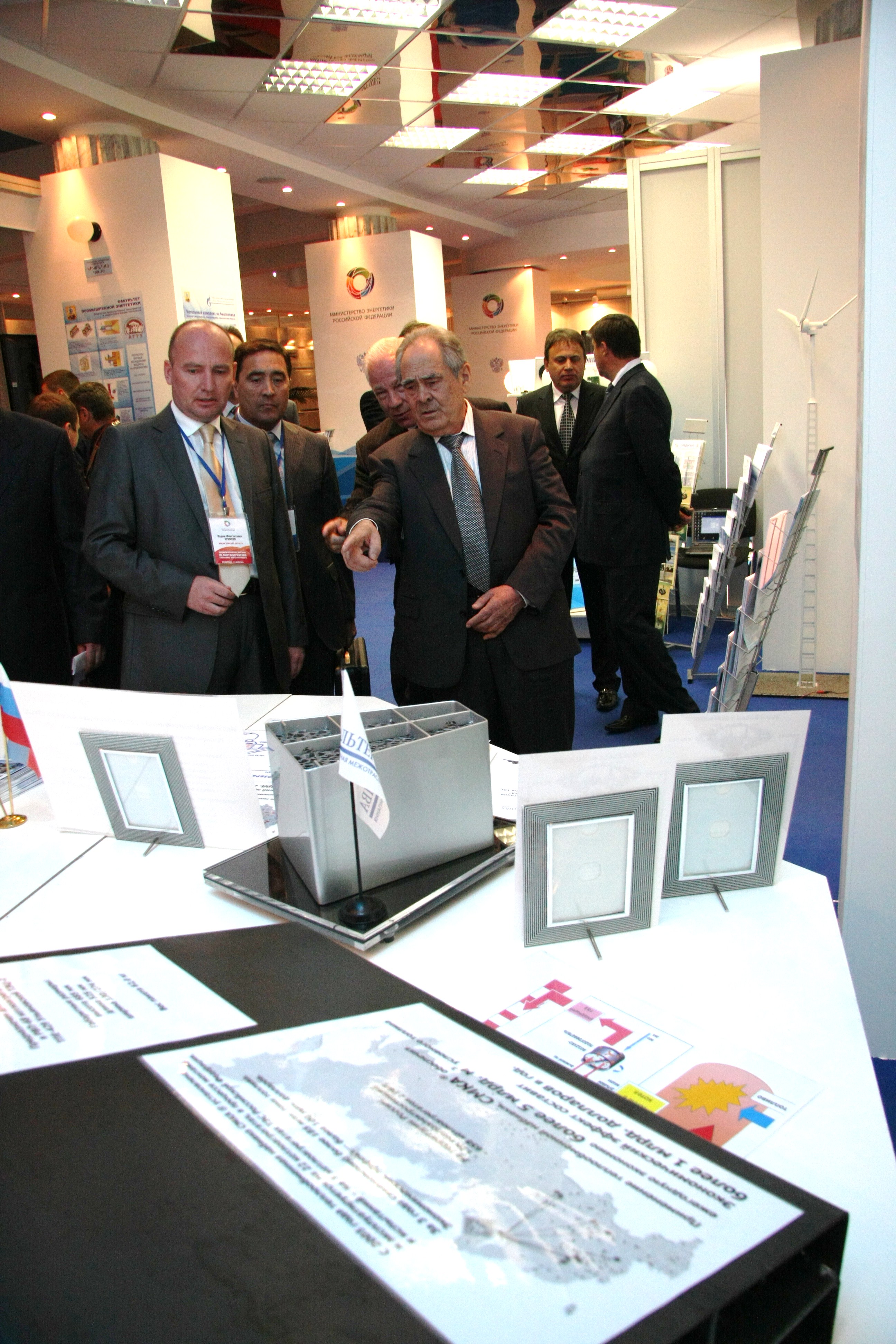

The company took part in the exhibition under the State Council of the Russian Federation on the topic "Energy Efficiency and Energy Saving", conducted by the President of the Russian Federation. Successful developments of the company were recognized as the best and marked by the diploma of the Minister of Energy of the Russian Federation. New developments were noticed by all the participants of the State Council, this has led interesting proposals on the application of new heat-exchange elements from various generating companies in different regions of Russia.

-

Participation of company’s working team in the work of the IV National Congress, dedicated to the priorities of the development of the Russian economy. The company was officially awarded a diploma.

-

We started supplying our product to Ukraine and Kazakhstan. The presentation in Turkmenistan expanded the geography of the company's interests in the Asian direction.

-

The developments of the company's specialists were actively used in the energy sector of Russia and the CIS and was recognized as the best.

-

The copyright for the design of CMKA® heat-exchange elements was protected in 11 countries of the world.

-

The certificate for the trademark CMKA® was issued, the production of the new heat elements began under its own brand.

-

The company was invited to participate in the Russian economic forum "Economics of Russia 21 century". The report on the effectiveness of the new product and new opportunities in the sphere of energy saving and energy efficiency caused a lot of positive feedback. The company was noticed at the governmental level.

-

The page with information about the company appeared in the federal manual "Fuel and Energy complex of Russia".

Specialists of the company successfully worked on ship repair.

-

The company was awarded an honorary diploma of international level in Antwerp, Belgium.

-

The first sales dealers of heat-exchange elements appeared.

The volume of orders for new production has again increased 3 times.

-

The production of heat-exchange elements of RAH was actively developing.

-

The volume of orders for heat elements has increased 3 times.

-

The production of innovative heat-exchange elements of regenerative air heaters (RAH) of boiler units of thermal power plants was opened.

-

Quality Management System was implemented.

-

Company received the approval and the certificate of the Russian Maritime Register of Shipping.

-

A contract for participating in the work under the international contract for the modernization of the Indian aircraft-carrying cruiser Vicramaditia was signed.

-

A contract with shiprepairing Center Zvyozdochka.

-

The assembly of units, sections and superblocks of the MISP Prirazlomnaya was completed. The weight of one superblock was 20,000 tons. The strict implementation of deadlines designated by the customer brought the company to the leading positions and had positive feedback from customer.

-

A contract for shipbuilding was signed with JSC PO Sevmash, in December 2003.

-

The volume of orders and objects for shipbuilding increased.

-

A license for repair and construction works was received, the company specialists carried out repair work on a number of facilities, including industrial ones.

-

The beginning of a new production area - shipbuilding and ship repair, the first teams of specialists performed ship repair work at nearby shipyards.

-

Participation in a large social project to renovation the city's passenger transportation park. 50 buses of LiAZ-677 were repaired and painted.

-

On February 24, a new company with a defiant name “The Alternative” Ltd. was registered with the aim to start production of heat-exchange surfaces of a new generation in the next

few years using the development of the Russian heat and power engineer Vladimir Komyagin.